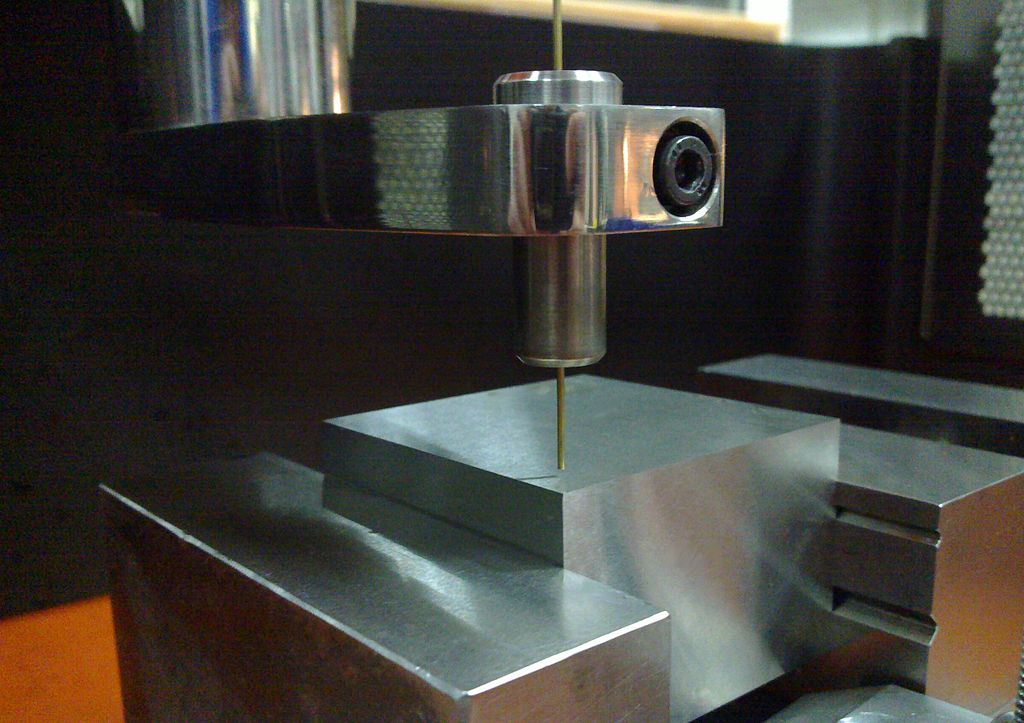

For over 50 years now the manufacturing industry has been constantly changing and updating the machinery and the technology which it uses for the various needs and functions within factories around the world. One of the biggest advancements which we have seen in manufacturing has been the invention of electrical discharge machining (EDM). This is a production process which uses electrothermal techniques that involve a single thread of metal wire, utilized with deionized water which conducts electricity, and its used as a highly efficient cutting machine. Wire EDM has without question transformed the industry of manufacturing and brought an untold amount of benefits. Let’s take a look at what those benefits have been, and how the process works.

Benefits of Using This Technology

Benefits of Using This Technology

The biggest benefit which using a wire EDM machine can bring is the heightened accuracy of the cut, this not only enables the manufacturers to deliver a higher quality result, but it also gives them much more scope in terms of the types of products that they are able to offer.

Another key benefit is that there is no impact cutting involved like there was in the past, which can create a lot of stress on the material that is being cut. This helps to reduce waste, avoid mistakes and deliver a far higher quality product.

Complex shapes can be cut with simplicity using wire EDM technology as well, owing to the flexibility of the metal wire which does the cut work. Intricate and complex shapes can all be delivered with consummate ease when using a machine such as an EDM wire cutter.

Ultimately this is a cutting system which is more accurate than laser, flame cut and even plasma cutting, and because of the fact that no force is placed on the material, the overall result is better and there is a huge reduction in waste, saving companies money on top of the other benefits.

How Does Wire EDM Work?

Wire EDM works by charging the wire that is doing the cutting through wire, the electrode of the machine and the work piece. As the spark of electricity jumps between the space of wire and work piece, it removes material and slices through the piece. During the cut a deionized liquid or non-conductive fluid will be used which helps to remove the waste that is being take off the work piece, as well as ensuring that the sparking process doesn’t short. The wire is continuously moving from a spool as the cut takes place which ensures that it is new wire that is constantly cutting, ensuring that the quality of the cut is highly precise and of good quality.

Who Uses It?

Wire EDM machines can be issued in just about every manufacturing industry, and it is most prominently seen in die cast cutting, for items such as tools, punches and dies, as well as thick plates which will be used in a number of different machinery. Simply put if it needs to be perfect and the cut is intricate, this is the machine that will be used.